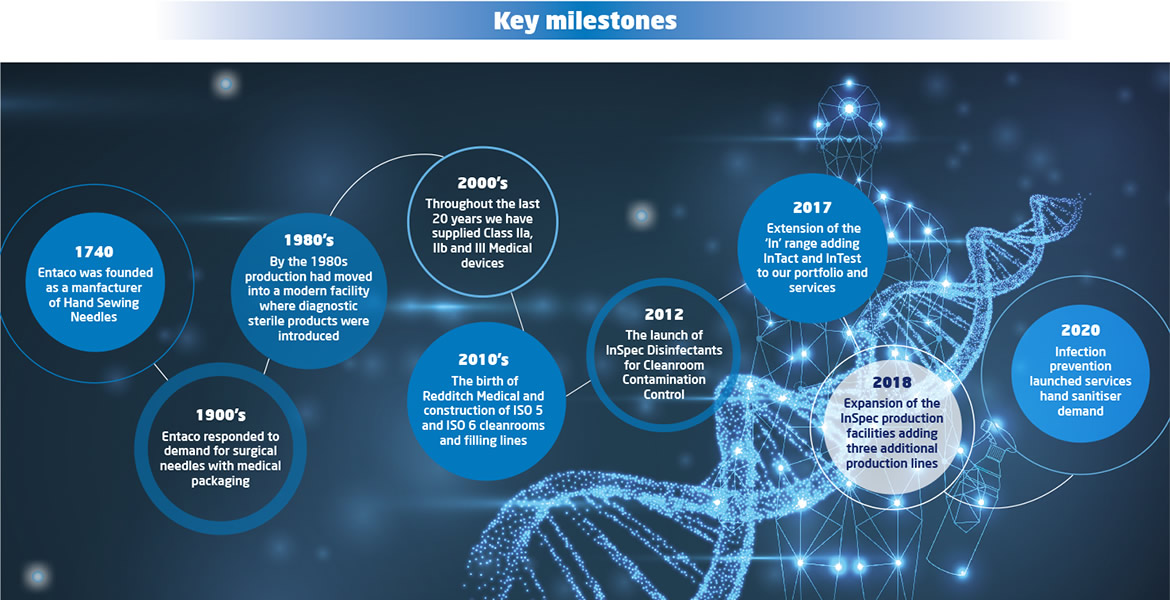

Our History

Formed in 1740, as part of the Entaco Group, Redditch Medical has almost 300 years manufacturing experience. Redditch Medical now provides medical devices to a global healthcare customer base, from start-up companies though to global corporations.

Company Profile

Whether your requirement is for a hospital, aseptic manufacturing facility or pharmaceutical manufacturing plant, we understand that rapid and flexible processes demand exacting products. Our solutions are designed by experience, with the end user in mind.

Our Primary Activities

- Cleaning

- Cleaning Agents

- Sterilisation

Profile

Here at Redditch Medical we have complete cleanroom contamination control solutions. Our InSpec product range covers all of your cleanroom needs - be that from the transfer process to routine & deep cleans.

We produce sporicides, biocides, alcohols and detergent formulations which are available sterile or non-sterile. The InSpec & InTact range is provided in a variety of formats and sizes such that all scales of cleanroom decontamination can be accommodated. The latest innovative format that InSpec products are available in is the unique burstable pouch biocidal and sporicidal wipes & mops.

Our friendly team will be more than happy to respond to enquiries about our products and services.

Our Experience

As trading division of Entaco Ltd, Redditch Medical has over 125 years of experience providing medical devices and supporting products worldwide to the lifesciences industry. Our broad range of products and services supports customers who need contract cleanroom cleaning and packaging services, control of sterilisation and regulatory support. We are proud of our customer network, with some relationship spanning the last 25 years. We offer a confidential, high quality and efficient service supported by an experienced team.

In more recent times, our experience has broadened to include manufacture and supply of cleanroom disinfectants and detergents (InSpec), CiP products (InTact) and Infection Preventions products.

Our Portfolio Range

We are proud of our customer portfolio supplying products worldwide, from start-up companies though to high-profile global corporations. InSpec is supported worldwide with a local and familiar distributor network who are experts in the contamination control and infection prevention field.

Confidential Service

We offer a confidential, innovative, high quality and efficient service through an experienced team from management to shop floor.

Please contact us for further details.

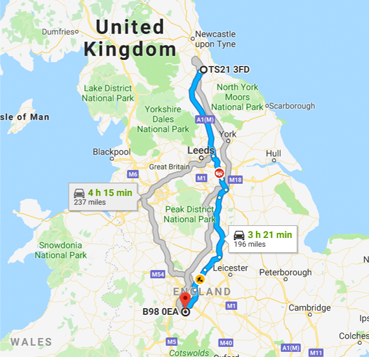

Our Sites

Redditch Medical is based over two sites which offer many options for manufacturing.

Enter your starting address/postcode and select a destination site:

Certification

Redditch

The Redditch site is situated 30 mins from Birmingham and has been the Head Office for the business for over 100 years. Conveniently located near Birmingham, Redditch has an excellent air, road and rail network.

On site we have a certified ISO 7 Cleanroom facility which has been designed and built for the manufacture and packaging of Class I, IIa, IIb, and III medical devices.

In addition, there is a 260 sq. mtr. ISO 9 Controlled Room for high volume product assembly. This controlled room has presses, assembly machines, sealing and thermoform sealing machines.

Our latest venture has seen the recent expansion into new premise, expanding our footprint by 650 sq. mtrs. This facility is the dedicated manufacturing facility for InSpec HG and HR, our hand sanitation products range.

Address

Units 46, 63 and 90, Heming Road, Washford Industrial Estate, Redditch, Worcestershire B98 0EA, England.

Sedgefield

Redditch Medicals InSpec® products are manufactured at our Sedgefield site in County Durham. This is located at the NETPark Discovery 2 site situated a short drive from Newcastle Airport, major rail routes and the A1M. A short journey down the A1M at Newton Aycliffe are our Warehouse and Logistic facilities.

On the 2,000 sq. mtr. site there are four production lines with ISO 5 and ISO 6 cleanroom facilities. Our facilities are purpose built and dedicated to Cleanroom Contamination Control Disinfectant and Detergent production which have been designed with critical product manufacture in mind.

All critical liquid filling is performed under ISO 5 conditions to match our critical products with pharmaceutical and medical device industries.

The facility also has a dedicated ATEX blending room, preparation areas and homes a WFI quality water system (Water for Injection) enabling high volume production of 1Ltr, 5Ltr, 500ml, and burstable wipes - both sterile and non-sterile variants.

Address

Manufacturing Site: Discovery 2, 2 William Armstrong Way, NETPark, Sedgefield, Co Durham, TS21 3FD, UK

Warehouse & Logistics: Unit 1,2 & 7 Northfield Way, Newton Aycliffe, Co. Durham, DL5 6EJ, UK